Introduction to Insert Molding.

In the world of modern production, insert molding has developed as a versatile and effective technique that provides multiple benefits to a variety of industries. This essay tries to provide a full review of insert molding, including its definition, historical evolution, and important role in modern production.

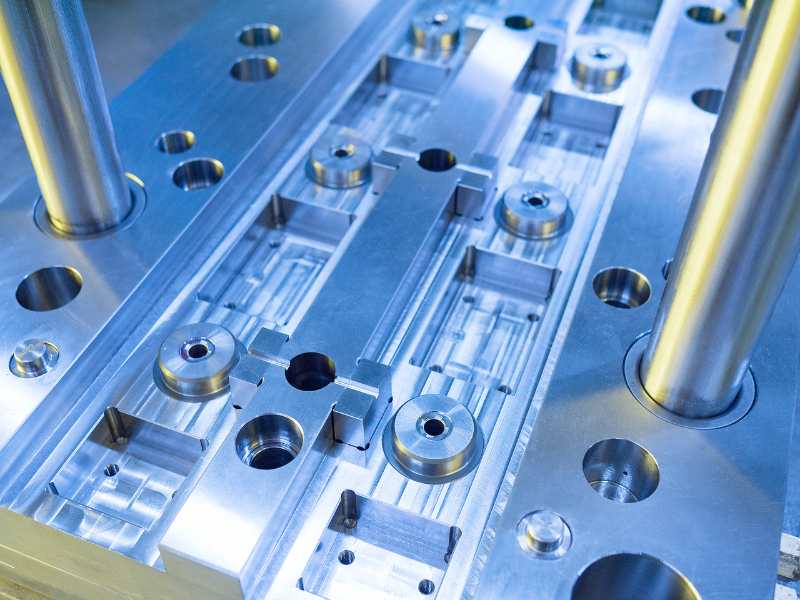

What is Insert Molding.

Insert molding, also known as overmolding or two-shot molding, is a specialized manufacturing method that combines the benefits of injection molding with the addition of extra components. In this process, a pre-formed insert, such as a metal, plastic, or electronic component, is inserted within a mold cavity, and then a second material, usually a thermoplastic polymer, is injected around the insert to produce a strong, cohesive connection. This procedure produces a highly integrated, multi-material product that perfectly mixes the desired qualities of the insert with the molded material, resulting in a long-lasting and useful end product.

Brief History and Development of Insert Molding.

Insert molding dates back to the early twentieth century, when the injection molding technology was first established. As technology advanced, manufacturers saw the opportunity to embed secondary components directly into molded items, resulting in the development of insert molding. In the 1950s and 1960s, the method gained widespread usage, particularly in the automotive and electronics industries, where the ability to blend disparate materials and improve product functioning became increasingly valuable.

The insert molding process has evolved significantly over time, thanks to advances in mold design, material research, and automation technologies. The introduction of computer-controlled injection molding machines, as well as the development of specific mold geometries and advanced molding materials, has greatly expanded insert molding’s capabilities and applications. Today, the method is used in a wide range of industries, including consumer electronics, medical devices, aerospace, and automotive components.

Importance and Applications in Modern Manufacturing.

The importance of insert molding in modern manufacturing cannot be understated. This adaptable method provides a plethora of benefits, making it a valuable tool in numerous industries:

Insert molding enables producers to develop products with greater usefulness by combining several materials, such as improved mechanical qualities, higher durability, and the insertion of electronic components or sensors.

Design Flexibility: The ability to add pre-formed inserts into the molding process allows designers to create more complicated, customizable, and inventive products that meet specific market demands.

Cost-Effectiveness: Insert molding can typically save money by lowering the number of assembly steps, minimizing the requirement for secondary operations, and streamlining the overall manufacturing process.

Improved Efficiency: The use of insert molding into automated manufacturing lines has resulted in higher production efficiency, lower manpower needs, and improved quality control procedures.

Sustainability: The capacity to mix multiple materials into a single, cohesive component can help to promote more sustainable manufacturing methods by reducing the need for separate parts and facilitating product recycling at the end of its life cycle.

Insert molding has found significant application in a variety of industries, including automotive, electronics, medical devices, consumer goods, and aerospace. In the automotive industry, it is utilized to make fuel system parts, door handles, and safety systems. In the electronics sector, insert molding is used to make integrated housings, connections, and enclosures for a variety of devices. In medicine, the method is used to create surgical instruments, prosthetic components, and medication delivery systems. The adaptability of insert molding continues to fuel innovation and open up new possibilities in modern manufacturing.

Basic Principles of Insert Molding

Insert molding is a specialized manufacturing technology that combines the benefits of injection molding with component assembly. This procedure entails incorporating a pre-made insert, such as a metal, plastic, or ceramic component, into a plastic part during the injection molding process. The end result is a composite structure that combines the desired qualities of the insert and the molded plastic, enabling for the production of complex and functional pieces in a single, efficient process.

Process Overview

Preparing the Insert: The insert, which can be composed of a variety of materials, must be well prepared before being inserted in the mold. This could include cleaning, surface treatment, or applying a coating to guarantee adequate bonding between the insert and the molded plastic. The insert is frequently constructed with features, such as undercuts or protrusions, to improve mechanical interlocking between the materials.

Placing the Insert in the Mold: Once prepared, the insert is placed in the mold cavity, either manually or automatically. The insert’s placement is crucial because it must be perfectly aligned to achieve the required end part geometry and the best dispersion of the molten plastic around it.

Injection of Plastic: The molten plastic is then injected into the mold cavity, encasing the insert. The plastic flow surrounding the insert is carefully managed to prevent air entrapment and provide complete coverage of the insert’s surface. The pressure and temperature of the injection process are carefully controlled to obtain the desired material characteristics and part quality.

Cooling and Ejection: Once the plastic has set, the mold is opened and the molded piece is ejected. The chilling cycle is a critical phase because it guarantees that the item solidifies properly and has dimensional stability. The expelled part is next inspected and, if necessary, post-processed.

Insert Types Used:

Metal inserts, such as steel, aluminum, or brass, are widely utilized in insert molding. These inserts add structural integrity, thermal conductivity, and corrosion resistance to the finished product. Metal inserts are commonly utilized in applications that require great strength, such as automobile parts, household appliances, and industrial equipment.

Plastic inserts, made of materials such as thermoplastics or thermosets, are employed when the desired qualities of the final item necessitate a combination of plastic and insert material. Plastic inserts can be used to construct complex geometries, perform specific duties, or add ornamental features to molded parts.

Ceramic inserts, composed of alumina, zirconia, or silicon carbide, have distinct qualities such as excellent heat resistance, electrical insulation, and chemical inertness. These inserts are commonly utilized in applications requiring the final item to survive extreme temperatures or harsh environmental conditions, such as electronics, aerospace, and medical.

Other Materials: In addition to metal, plastic, and ceramic inserts, insert molding can use a variety of other materials such as wood, glass, and natural fibers. The choice of insert material is determined by the application’s unique needs, such as the desired mechanical, thermal, or aesthetic attributes of the final item.

Comparison to Traditional Injection Molding

Insert molding has various advantages over regular injection molding.

Improved Part Functionality: Incorporating inserts into the molded part can improve the overall functionality of the finished product by adding attributes such as increased strength, electrical or thermal conductivity, corrosion resistance, or specialized surface treatments.

Insert molding removes the need for separate assembly stages by merging several components into a single molded product, resulting in reduced manufacturing time and cost.

Increased Design freedom: The ability to incorporate a variety of insert materials into the molded part provides increased design freedom, allowing for the construction of more complicated and personalized products.

Enhanced Quality Control: Controlled insert placement within the mold cavity can increase the uniformity and reliability of the finished product, lowering the possibility of flaws or deviations.

Overall, the Basic Principles of Insert Molding highlight the versatility and effectiveness of this production technology. By intelligently incorporating pre-made inserts into the injection molding process, manufacturers may produce high-quality, multi-functional parts that fulfill the changing needs of many industries.

Materials Used in Insert Molding: A Comprehensive Examination.

One of the most important issues in insert molding is material compatibility. The insert material must be resistant to the high temperatures and pressures associated with the injection molding process, as well as the chemical and physical stresses exerted during the part’s intended use. Metals such as steel, aluminum, and brass are commonly used insert materials, as are engineered thermoplastics such as polyetheretherketone (PEEK) and polyamide (nylon).

Metallic inserts are commonly used in applications requiring great strength, durability, and temperature resistance. These inserts can give structural integrity, load-bearing capacity, and the ability to tolerate high temperatures. However, the complexity of the insert shape, as well as the requirement for perfect alignment throughout the molding process, might provide issues. To achieve a stable and dependable bond, manufacturers must carefully evaluate the thermal expansion properties of both the metal insert and the surrounding polymer.

In contrast, thermoplastic inserts provide greater design flexibility and simplicity of integration into the injection molding process. These components can be precisely molded into complex geometries and easily incorporate features like threads, snap-fits, and living hinges. The thermal expansion behavior of thermoplastic inserts is frequently more similar to that of the surrounding polymer, resulting in a stronger and more durable bond. Furthermore, thermoplastic inserts can be fitted with functional elements such as electrical connectors or sealing features, which improve the finished product’s capabilities.

The choice of polymer material for the molded component is equally important in insert molding. The polymer must be compatible with the insert material, with good adhesion and wetting qualities to ensure a strong attachment. Engineering thermoplastics such as polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and glass-filled nylon are popular materials for insert molding. These materials provide a variety of mechanical, thermal, and chemical qualities to satisfy the specific needs of the application.

In addition to material compatibility, the design of the insert and mold geometry are critical to the success of the insert molding process. Surface polish, undercut features, and mechanical interlocks can all have a major impact on the strength and integrity of the bond between the insert and the molded component. Mold design issues, including as gate positioning, cooling channels, and part ejection mechanisms, must be carefully planned to enable consistent and dependable manufacture of high-quality insert-molded components.

Because of its versatility, insert molding is widely used in a range of industries, including automotive and aerospace, electronics, and medical equipment. This manufacturing technology enables the integration of functional components, improved structural performance, and the use of complex geometries, making it an invaluable tool for product designers and engineers.

As technology advances and the demand for innovative, integrated products develops, knowing the materials and design issues in insert molding will become increasingly important. Manufacturers may realize the full potential of insert molding by carefully selecting the right materials and optimizing the manufacturing process, offering high-performance, dependable, and cost-effective products to satisfy the market’s changing needs.

Insert Molding Techniques: An Exploration

Overmolding, often called two-shot or multi-shot molding, is one of the most used insert molding processes. In this procedure, the insert component is placed in the mold cavity, and the plastic material is injected around it to make a strong, permanent bond. This method is very beneficial for making seals, gaskets, and enclosed electronic components, as the plastic material provides protection, structural integrity, and aesthetic appeal.

Co-molding is another frequent insert molding process in which two or more materials are injected into a single mold at the same time. This technology enables the production of complicated, multi-material parts in a single phase, avoiding the need for separate assembly operations. Co-molding is commonly utilized in the manufacture of toothbrush handles, where the stiff plastic body is paired with a soft, overmolded grip to improve comfort and control.

Compression molding is a type of insert molding that is best suited to larger or more complex insert components. In this technique, the insert is inserted in the mold, and the plastic material is compressed around it to form a robust, integrated part. This technology is frequently used in the production of automotive components including steering wheel inserts and instrument panel components, where the insert provides structural support or functional integration.

Insert injection molding, on the other hand, is the process of sequentially injecting numerous materials into a single mold cavity. In this method, the insert component is first inserted in the mold, and then the principal plastic material is injected around it. This is followed by the injection of a secondary material, which can act as a decorative cover, functional feature, or protective layer. This technology is widely employed in the manufacture of electronic housings, where the insert component may offer structural support or electrical shielding.

In addition to these established procedures, new types of insert molding have evolved in recent years to meet the ever-changing needs of various industries. For example, in-mold assembly (IMA) combines the insert molding process with the assembly of extra components, enabling for the production of highly integrated, multi-functional parts in a single manufacturing step. Similarly, insert overmolding, a procedure that combines insert molding and overmolding, allows for the development of complex, multi-material parts with improved aesthetic and functional properties.

Each of these insert molding techniques has distinct advantages and is designed for certain applications and needs. The complexity of the part, the materials involved, the intended mechanical and functional attributes, as well as manufacturing volume and cost concerns, all influence the process chosen. As the need for innovative, multifunctional goods grows, the insert molding technique continues to be an important tool in modern production, allowing for the smooth integration of various materials and capabilities into a single, cohesive component.

Benefits of Insert Molding: Improved Product Design and Manufacturing Efficiency

One of the key benefits of insert molding is its ability to expedite the manufacturing process. Insert molding saves time and effort by merging many components into a single, integrated item. This integration not only reduces the amount of parts needed, but it also lowers the chance of errors and increases overall manufacturing efficiency. Manufacturers can now achieve faster turnaround times, cheaper operating costs, and improved product uniformity.

Another significant advantage of insert molding is its flexibility in material integration. This approach allows designers to effortlessly blend a variety of elements, such as metals, plastics, and electronics, into a single, coherent component. This flexibility enables the development of sophisticated, multifunctional goods that meet the changing needs of the market. For example, in the automotive industry, insert molding allows for the integration of electrical sensors, metal inserts, and plastic housings into a single, high-performance component, improving the vehicle’s overall functionality and performance.

Furthermore, insert molding provides greater design flexibility, allowing producers to create detailed, custom-tailored products that match the specific needs of their clients. Insert molding enables the creation of unique product designs that were previously difficult, if not impossible, to produce using traditional production methods. This design flexibility leads to better product performance, aesthetics, and overall user experience.

In addition to its design advantages, insert molding has high structural integrity and longevity. The strong bond formed between the integrated components during the molding process produces a durable and long-lasting product that can endure the rigors of daily use. This improved structural integrity is especially useful in applications that need high reliability and safety, such as the medical and aerospace industries.

Furthermore, insert molding reduces the requirement for post-processing activities like assembling, welding, and fastening, which saves money significantly. Insert molding reduces the need for these additional manufacturing steps by combining several components into a single item, resulting in decreased production costs and increased profitability.

Finally, insert molding offers numerous benefits, including efficiency, design, material integration, and cost reductions. As industries demand more inventive, high-performance, and cost-effective products, insert molding’s adaptability and capabilities make it a more appealing and necessary manufacturing solution. By embracing this advanced technology, firms can open up new avenues for product innovation, gain a competitive advantage, and ultimately provide higher value to their customers.

Essay on the Challenges and Limitations of Insert Molding.

Insert molding has several advantages, but it also has some drawbacks and restrictions. In this essay, we will look at the main obstacles and limitations of this technology, highlighting the elements that designers and manufacturers must consider when using insert molding.

One of the key obstacles of insert molding is the process’s intricacy. Insert molding involves careful control over a number of variables, including material compatibility, insert location, and mold design. Improper management of these parameters can result in a variety of problems, including insufficient encapsulation, warping, and delamination of the insert from the plastic component.

Another key problem is the need for tight tolerances and alignment during insert insertion. The insert must be precisely positioned within the mold cavity to ensure consistent part quality and the intended functioning of the finished product. Any misalignment or movement of the insert might lead to changes in wall thickness, unequal stress distribution, or even part failure.

Furthermore, the thermal expansion and shrinkage properties of the plastic and insert materials must be precisely matched to reduce residual stresses and potential deformation of the finished item. Differences in these qualities might cause problems such as warping, cracking, or delamination, jeopardizing the structural integrity and performance of the insert-molded component.

In addition to technological obstacles, insert molding has economic and logistical limits. Insert molding tooling is often more sophisticated and expensive than regular injection molding tooling because it must accommodate the additional insert components while also ensuring accurate placement and integration. This higher tooling cost can be prohibitive for some producers, especially for low-volume or prototype production.

Furthermore, the insert molding process can be more time-consuming and labor-intensive than other manufacturing methods since it frequently includes additional procedures such as insert preparation, positioning, and inspection. These characteristics can have an impact on the overall production efficiency and cost-effectiveness of the process, making it less appealing for specific applications or production circumstances.

Another constraint of insert molding is the restricted number of materials that can be successfully mixed. Not all materials are compatible with one another, and the plastic and insert materials must be carefully chosen to achieve a strong and dependable attachment. Incompatible materials might cause poor adhesion, delamination, or even chemical reactions, jeopardizing the performance and longevity of the finished item.

Finally, the complexity of the insert molding process can provide difficulties in terms of quality control and inspection. Detecting flaws or irregularities in the finished item can be more difficult due to the combination of the insert and the plastic component. Specialized inspection procedures and quality control measures may be necessary to assure consistent manufacturing of high-quality insert-molded products.

To summarize, while insert molding provides significant benefits in terms of component integration and functional optimization, it also presents a number of problems and constraints that designers and manufacturers must carefully traverse. From the process’s complexity and the need for tight tolerances to economic and material compatibility considerations, successful insert molding implementation necessitates a thorough understanding of the process as well as a thorough consideration of the various factors that can influence the final product quality and performance.

Applications for Insert Molding

One of the most common applications of insert molding is in the automotive industry. Dashboard panels, door knobs, and center consoles are examples of automotive components that frequently need the integration of metal inserts, electronic circuitry, and other functional parts. Insert molding enables producers to create these intricate pieces in a single, streamlined process, lowering assembly time and costs while maintaining accurate tolerances and high-quality finishes.

Another industry that has widely employed insert molding is electronics. Insert molding is used by manufacturers of electronic goods ranging from cellphones to home appliances to seamlessly incorporate numerous components such as switches, sensors, and connectors into the product’s design. This approach allows for the production of compact, lightweight, and durable electronic assemblies that can resist the demands of daily operation.

In the medical and healthcare industries, insert molding is critical in the fabrication of medical devices and implants. Insert molding provides the precision and variety needed for these sensitive applications, ranging from orthopedic prosthesis with metal components for strength and stability to drug delivery systems with specific drug-eluting inserts. Furthermore, the ability to directly mold biocompatible materials onto inserts assures that these medical devices are both safe and effective.

Insert molding’s capabilities have also been beneficial to the building and infrastructure industries. The insert molding process allows structural components, such as reinforced concrete panels or composite construction materials, to integrate metal inserts or other reinforcing elements. This integration improves the strength, durability, and overall performance of these construction materials, allowing them to endure the demands of the built environment.

Aside from these industries, insert molding is used in a wide variety of consumer products, such as sports equipment, household goods, and toys. The ability to seamlessly integrate several materials and components into a single part enables designers to build creative, useful, and visually appealing products that meet consumers’ changing demands and tastes.

Insert molding’s versatility extends to the fabrication of specific industrial components such as electrical connectors, hydraulic fittings, and machinery parts. In these applications, the technology allows for the fabrication of complicated, high-precision parts that meet strict performance and safety standards.

As technology advances and product designs become more complex, the value of insert molding in modern manufacturing cannot be emphasized. This unique technique enables engineers and designers to push the limits of what is feasible, opening up new avenues for product creation, performance enhancement, and cost efficiency. Insert molding has become a crucial instrument in the armory of manufacturing excellence because it smoothly integrates varied materials and components, allowing the fabrication of exceptional products that satisfy the ever-changing demands of the global marketplace.

There are many aluminum casting parts are used for insert molding in many applicances, you can go to die casting mold page to know more about die casting.

Design Considerations For Insert Molding

To begin, it is critical to select the suitable insert material. To achieve a strong and stable bond, the insert, which can be constructed of a variety of materials including metal, plastic, and ceramic, must be compatible with the molding plastic of choice. Thermal expansion coefficients, surface roughness, and chemical compatibility must all be carefully examined to reduce the danger of delamination or other structural failures.

Equally important is the design of the insert. The form, size, and geometry of the insert can have a considerable impact on how the molten plastic flows during the injection process. The placement of the insert within the mold, as well as any characteristics or protrusions that may interfere with the plastic’s ability to entirely encapsulate it, must be carefully considered. The insert’s proper shape can also help to remove air pockets more efficiently and minimize sink marks or other surface flaws.

The mold design itself is an important factor in the success of an insert molding project. The mold must be designed to accept the insert while maintaining a secure and exact fit. This may entail including specialized features, such as pins or locating devices, to keep the insert in place during the injection procedure. The mold design must also take into account the flow patterns of the molten plastic, optimizing the gating system and runner design to achieve uniform filling and reduce residual stresses in the finished item.

In addition to the physical design factors, the insert molding process parameters must be carefully examined. Melt temperature, injection pressure, and cooling time are all variables that can have a substantial impact on the finished part’s quality and function. Extensive testing and tuning may be required to determine the best process parameters for a specific material and insert combination.

Furthermore, post-processing factors, such as the possibility of additional operations (e.g., trimming, deburring, or surface finishing), must be considered during the design phase. These additional stages can have a considerable impact on the entire cost and lead time of the manufacturing process, thus they must be considered during project planning.

Finally, analyze the insert-molded part’s intended use and performance criteria. Mechanical load, environmental exposure, and regulatory standards must all be carefully considered to guarantee the design satisfies the appropriate specifications and safety criteria. Simulation and testing may be required to validate the design and guarantee it is appropriate for the intended usage.

In conclusion, the design concerns for insert molding are numerous and necessitate a thorough grasp of materials, mold design, and production processes. By carefully addressing these issues, designers and engineers may improve the insert molding process, resulting in high-quality, long-lasting, and cost-effective products that suit the demanding needs of modern businesses. As the demand for innovative and integrated solutions grows, a thorough and intelligent design approach to insert molding will become increasingly important.

We are one of top 10 mold manufacturers and aluminum die casting manufacturers in China, if you are looking for any type of injection molding service, contact us.